The ongoing 4th Industrial Revolution has shifted the traditional paradigm of producing medical devices. Additive Manufacturing (AM), a mould-less technology commonly referred to as 3D printing, plays an essential role in the shift taking place in this field.

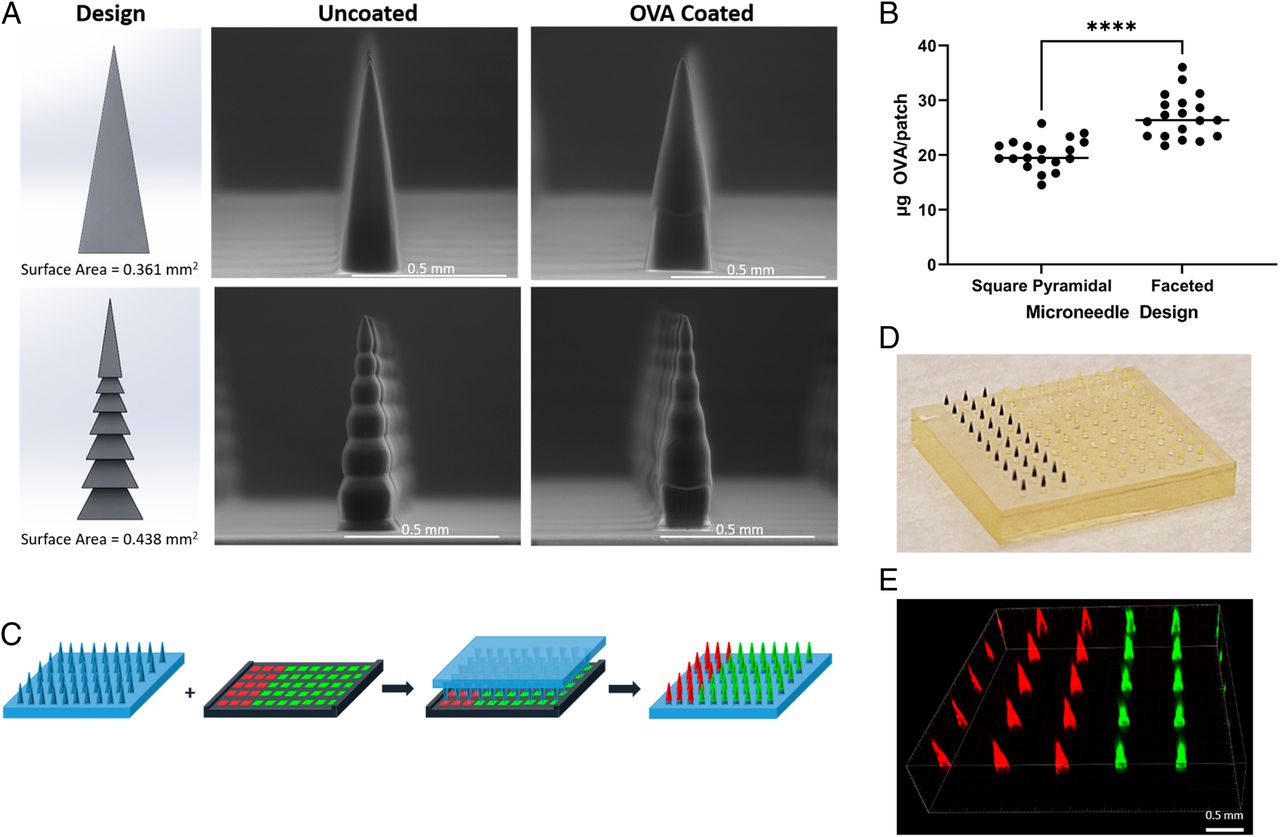

Because of the high degree of geometrical freedom that can be achieved, AM is being used to conceive polymeric microneedles (MNs) with tailored design. For instance, Caudill and co-workers (2021) studied the benefits of microneedle vaccination over the traditional subcutaneous one. An AM process that relies on resin photopolymerization (i.e., continuous liquid interface production) was used to fabricate the MNs in two different shapes: square pyramidal and faceted (cf. image given in this post).

Cargo loading was performed via surface coating and assessed for the different MN designs. Whilst surface area increased 21.3%, cargo loading augmented 36% from square pyramidal to faceted with horizontal grooves, which pinpoints the importance of geometry design to loading biologics on MNs. Furthermore, transdermal delivery through MN vaccination was more effective in triggering primary antigen-specific IgG as well response duration when compared to subcutaneously or intradermally delivering paths.

Caudill et al. (2021) findings represent a major step towards a simpler, effective, and pain-free vaccination process that can potentially increase global vaccination. Furthermore, this self-administered vaccination path may aid in prompt responses during epidemic and pandemic scenarios. In that sense, AM has proved to be a feasible manufacturing route for improving drug delivery systems via tailored shapes and geometries.

Read more of this fascinating paper here: Transdermal vaccination via 3D-printed microneedles induces potent humoral and cellular immunity

This post was written by Pedro Luiz Lima dos Santos as part of an ongoing series of scientific communications written and curated by BioTrib’s Early Stage Researchers.

This post was written by Pedro Luiz Lima dos Santos as part of an ongoing series of scientific communications written and curated by BioTrib’s Early Stage Researchers.

Pedro is researching the Functional Biotribology of the Surface Engineering of 3D Printed Components at the University of Leeds, UK.