Sometimes unexpected events occur at unexpected times, providing inspiration for medicine. In this instance, it pertains to ophthalmology, more specifically intraocular lenses, and it occurred during World War II. Intraocular Lenses (IOLs) are optical lenses that can correct refractive defects by being implanted in the eye. IOL-based cataract surgeries are currently one of the most popular and safest surgical procedures performed globally. (Yu, 2018)

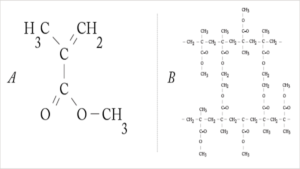

The Second World War did, in fact, mark the genuine commencement of the IOL. Harold Ridley was a civilian ophthalmologist, who were operating on Royal Air Force pilots who suffered eye injuries, engaged in aerial combat over the South of England. On August 15, 1940, he underwent 19 surgeries on a pilot, whose Perspex canopy had shattered, sending numerous splinters of poly(methyl methacrylate) (PMMA, Figure 1) into his eyes.

He discovered that the PMMA splinters, unlike glass splinters, remained inert in the patient’s eye and that the immune system had not responded to them during the course of the treatment. Ridley came to the realisation that PMMA could be utilised to create artificial lenses that could be inserted into the eye to replace the natural lenses that had been removed during cataract surgery. (Kretz, 2014)

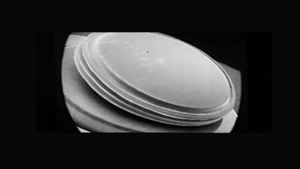

He then, together with the Rayner Optical Company, produced the first IOL (Figure 2) adopting ICI’s Transpex I, a high quality version of PMMA. On November 29, 1949, at St Thomas’ Hospital, London, Ridley performed surgery inserting the first lens into a 42-year-old woman after an extracapsular cataract excision. (Scholtz, 2006)

Today, millions of people’s lives have been made better thanks to Ridley’s brilliance. IOLs are now widely used for refractive outcomes improvement throughout clear lens exchange, not just during cataract surgery. The quality of vision following cataract surgery has never been greater in the developed world thanks to the incremental advancements in IOL design.

Take-Home Message: always keep an open mind, you never know where the next important medical discovery might come from!

References

Yu, N. F. (2018). State of the art of intraocular lens manufacturing. The International Journal of Advanced Manufacturing Technology, 1103–1130.

Scholtz, S. (2006, September). An Ophthalmic Success Story: The History of IOL Materials. From CRSTEurope: https://crstodayeurope.com/articles/2006-sep/0906_18-php/

Kretz, F. S. (2014, May 19). A Brief History of IOL Materials. From theOphthalmologist.com: https://theophthalmologist.com/subspecialties/a-brief-history-of-iol-materials

This article was written by Elisa Bissacco as part of an ongoing series of scientific communications written and curated by BioTrib’s Early Stage Researchers.

She is studying a PhD in Tribological Characteristics of Nanofibrous Electrospun Materials at ETH Zurich.