On September 1st 2022, at the University of Leeds, we had the honour to attend a presentation from Dr Paul Bills, reader of the BioMetrology group at the University of Huddersfield and co-investigator in the EPSRC Future Metrology Hub. His lecture – titled “Challenges in medical device development: using metrology to unlock the answers” – tackled significant aspects of advanced metrology tools that help assess personalised medical devices. This is of great relevance due to the current paradigm shift in the fabrication of these high-added value components via incorporating additive manufacturing (AM) in their production chain.

Watch Paul Bills leacture on the Challenges in medical device development: using metrology to unlock the answers below:

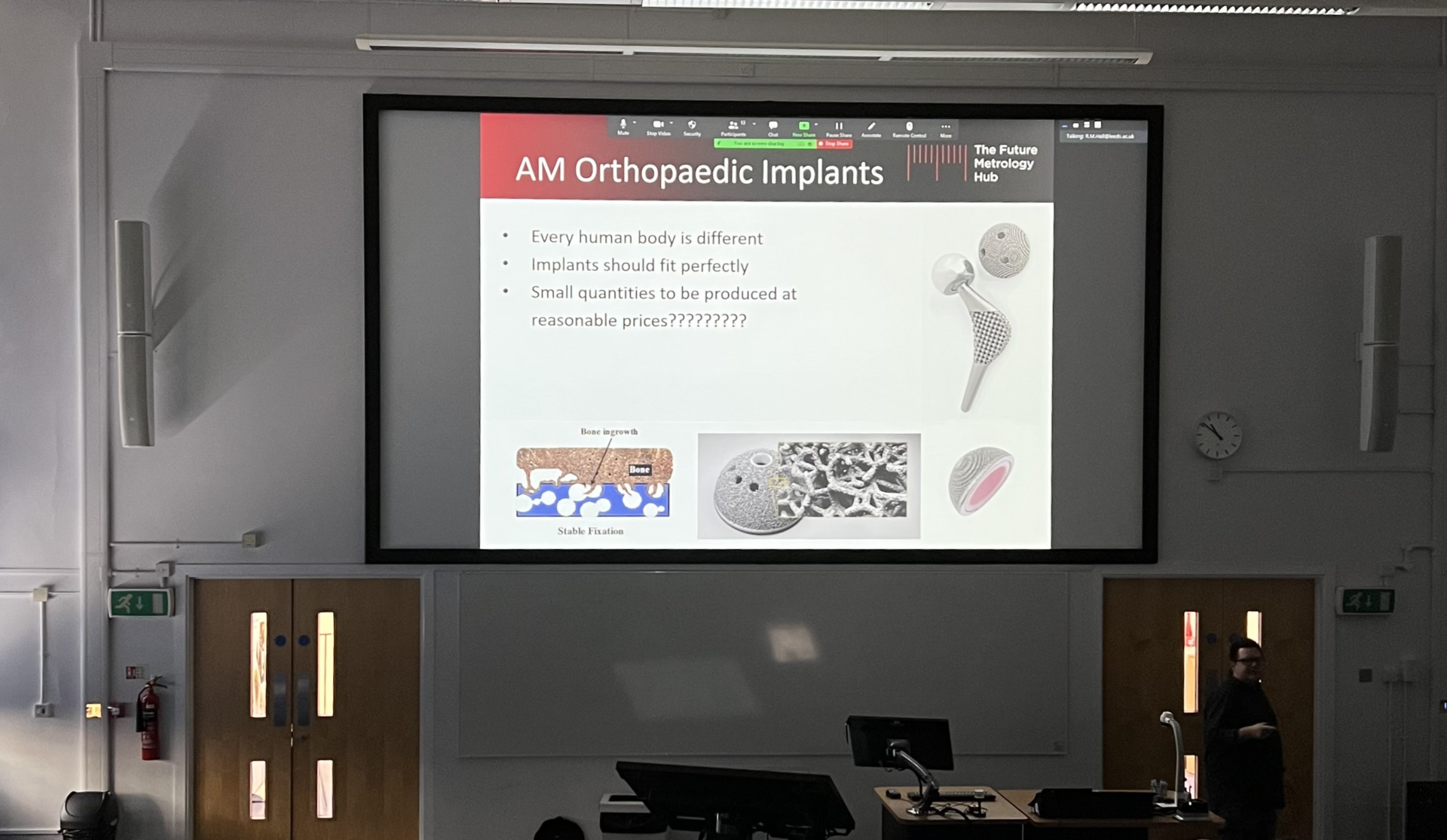

Dr Bills lecture went beyond the usual citation of the well-known advantages of AM in the orthopaedic field (e.g., high degree of customisation, sustainability, short lead time). One interesting topic that was discussed regarded the current gap in the literature regarding the interplay between osseointegration and infection in additively manufactured orthopaedic porous implants. These AM trabecular-like structures need further microbiological testing because they might be potential sites for deep and late infection. Furthermore, the lack of specification for components conceived by AM which possess an intricate geometry is another challenge yet to be overcome. In-situ metrology techniques could be employed to address that issue. In short, even though many advancements have been made in understanding the behaviour of AM orthopaedic implants, there is still a lot to be discovered from a metrology point of view. Understanding these will be important in ensuring the reliability of the technology for the production of implants in the orthopaedic field.

This post was written by Pedro Luiz Lima dos Santos as part of an ongoing series of scientific communications written and curated by BioTrib’s Early Stage Researchers.

Pedro is researching the Functional Biotribology of the Surface Engineering of 3D Printed Components at the University of Leeds, UK.