Graphene and its derivatives are the most studied 2D materials in general. TMDs, h-BN, BP, TMOs, and MXenes are among the other 2D materials that have been intensively studied. MXene nano-sheets are a new family of layered transition metal carbides, nitrides, or carbonitrides, with Ti3C2Tx being the most prominent member. MXenes have high electrical conductivity, mechanical characteristics, tunable surface chemistry, and inherent antibacterial/antiviral capabilities, making them particularly attractive for biological applications[1]–[4].

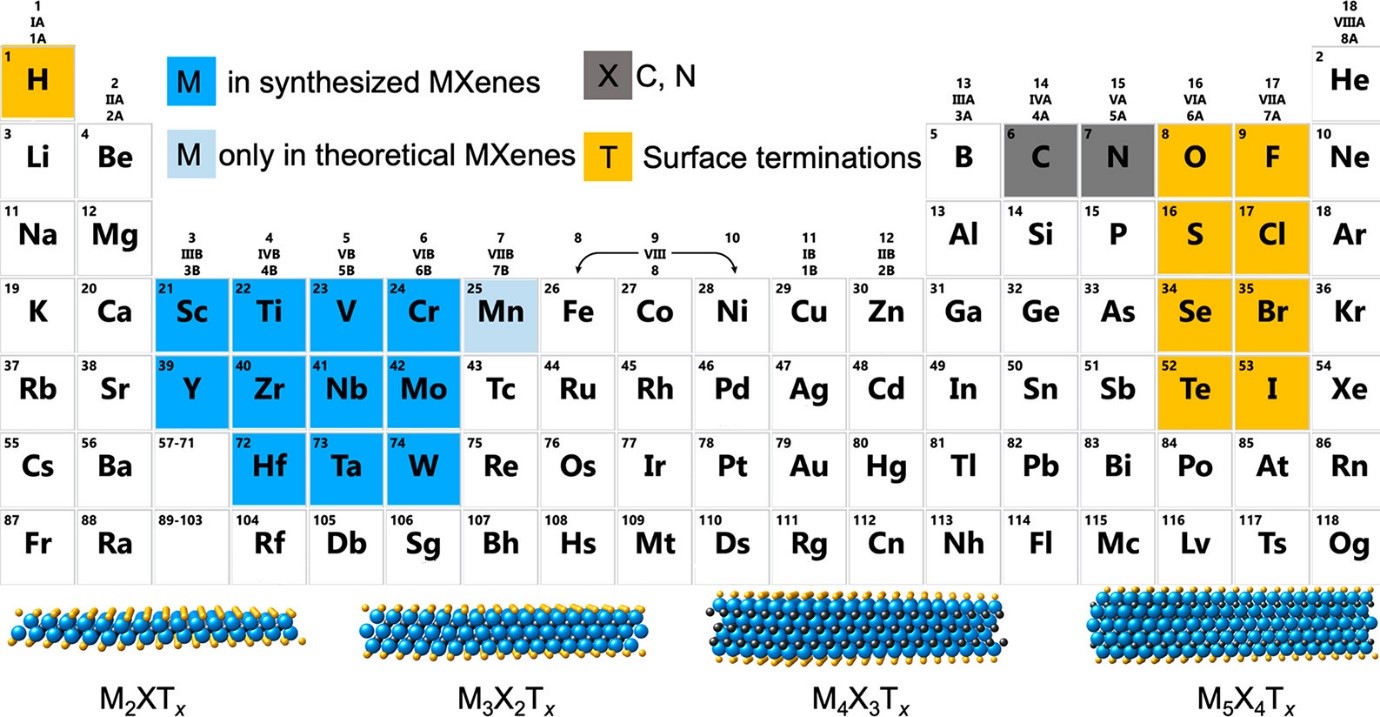

The general formula of MXenes is: Mn + 1XnTx

M, X, and T can be represented by a variety of elements, as shown in the periodic table above[5]. MAX phase precursors are used to make MXenes. 2D structures, such as surface terminations, are defined by the ending -ene. The same mechanical exfoliation processes that were utilized to separate the graphene layer from the graphite are employed to synthesize MXenes. However, selective etching is commonly utilized due to the low volume of production with mechanical exfoliation.

The mechanical and tribological properties are influenced by the transition metal, surface terminations, and monolayer thickness[1], [2]. As a result, it can be employed as lubricant additives, lubrication coatings, and composite fillers. Its application as a solid lubricant has been extensively investigated, although its usage as a reinforcement is still in its early stages. Tribological study for few and multilayer of Ti3C2Tx as solid lubricant using air spraying on stainless steel has shown that multilayer MXenes exhibited the low COF compared to the few layer MXenes. Another study found that employing a solid lubricant layer improved tribological properties[3]. MXenes have also been shown to decrease microstructural changes in materials and to efficiently transfer tribofilm to the counter surface, resulting in improved tribological characteristics. MXenes have a longer normalized wear life than other 2D solid lubricants, and they can achieve super lubricity if the experimental conditions are optimized [4].

The most remarkable aspect regarding their use in biotribological applications is their intrinsic biocompatibility combined with antibacterial and antiviral capabilities, which is true for several 2D materials like graphene, GO, rGO, MXenes, MoS2, and others [6], [7]. Despite the fact that MXenes is still in its infancy, its popularity is constantly increasing.

You can learn more by watching Philipp Grützmacher’s webinar and going through the references.

MXenes: A Model Material for Solid Lubricants | Surface Ventures

This article was written by Dilesh Raj Shrestha as part of an ongoing series of scientific communications written and curated by BioTrib’s Early Stage Researchers.

Dilesh is researching the Development of 3D-printable, self-lubricated polymer composites with improved wear resistance for total joint replacement at Luleå University of Technology, Sweden.

References

[1] Y. Gogotsi and B. Anasori, “The Rise of MXenes,” ACS Nano, vol. 13, no. 8, pp. 8491–8494, Aug. 2019, doi: 10.1021/ACSNANO.9B06394/ASSET/IMAGES/MEDIUM/NN9B06394_0005.GIF.

[2] J. Huang, Z. Li, Y. Mao, and Z. Li, “Progress and biomedical applications of MXenes,” Nano Select, vol. 2, no. 8, pp. 1480–1508, Aug. 2021, doi: 10.1002/NANO.202000309.

[3] X. Lin et al., “Fascinating MXene nanomaterials: emerging opportunities in the biomedical field,” Biomaterials Science, vol. 9, no. 16, pp. 5437–5471, Aug. 2021, doi: 10.1039/D1BM00526J.

[4] A. Zamhuri, G. P. Lim, N. L. Ma, K. S. Tee, and C. F. Soon, “MXene in the lens of biomedical engineering: synthesis, applications and future outlook,” BioMedical Engineering Online, vol. 20, no. 1, pp. 1–24, Dec. 2021, doi: 10.1186/S12938-021-00873-9/METRICS.

[5] Y. Gogotsi and Q. Huang, “MXenes: Two-Dimensional Building Blocks for Future Materials and Devices,” ACS Nano, vol. 15, no. 4, pp. 5775–5780, Apr. 2021, doi: 10.1021/ACSNANO.1C03161/ASSET/IMAGES/MEDIUM/NN1C03161_0003.GIF.

[6] X. le Hu et al., “Low-dimensional nanomaterials for antibacterial applications,” Journal of Materials Chemistry B, vol. 9, no. 17, pp. 3640–3661, May 2021, doi: 10.1039/D1TB00033K.

[7] Z. Tu, G. Guday, M. Adeli, and R. Haag, “Multivalent Interactions between 2D Nanomaterials and Biointerfaces,” Advanced Materials, vol. 30, no. 33, p. 1706709, Aug. 2018, doi: 10.1002/ADMA.201706709.