With the introduction of the new volumetric 3D printing technique known as Xolography[1], the conventional approach of layer-by-layer printing in additive manufacturing is altered. To harden the resin, it uses two different types of wavelengths and various initiators. In comparison to conventional photopolymerization techniques, this speeds up the process and produces a smoother surface with more material options.

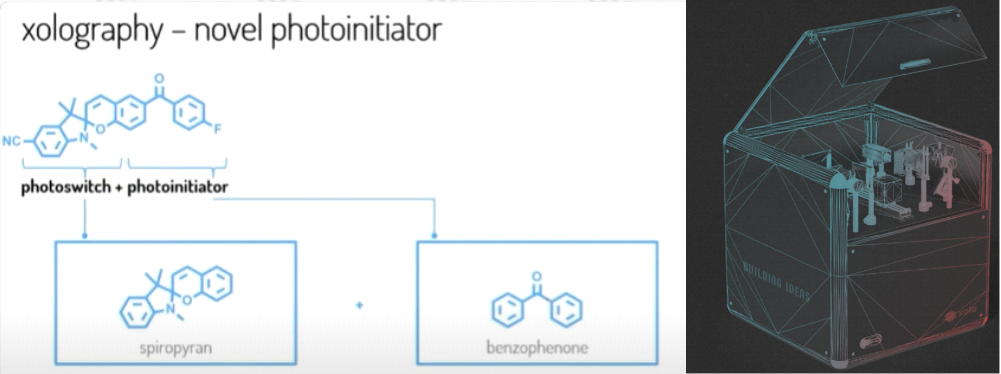

A new company using this technology, Xolo3D, has published a paper in nature [1]. The brief video about this technology is available here Xolography. See the header image which shows The Xcube: Volumetric 3D printer and new photoinitiator from Xolo3D [1].

How it is different from the other 3D photopolymerization techniques?

Xolography is a dual color volumertric 3D printing process and uses the light to cure the photoresin similar to the SLA/DLP printers. However, Xolography employs the novel kind of initiator. When the single wavelength light strikes this initiator, the curing process does not begin. It takes two wavelengths of light (blue and red) to start photopolymerization, and the initiator cures wherever the two wavelengths of light meet.

This has some limitations as well:

⦁ Transparent resins are required (as printing zone is bigger and avoidance of absorption of light is necessary)

⦁ Highly viscous resins (in order to prevent from sinking after they have been printed and to avoid any kind of support structures)

This innovative technology makes printing faster, smoother (no polishing is necessary), and more material possibilities. This technology, specifically bioprinting techniques like printing high-resolution hydrogels, has enormous potential in the medical field.

More interested readers are guided to the nature paper and webinar from the R &D manager of Xolo3D. Webinar by Niklas König

References:

[1] Regehly M, Garmshausen Y, Reuter M, König NF, Israel E, Kelly DP, Chou CY, Koch K, Asfari B, Hecht S. Xolography for linear volumetric 3D printing. Nature. 2020 Dec;588(7839):620-624. doi: 10.1038/s41586-020-3029-7. Epub 2020 Dec 23. PMID: 33361791.

This article was written by Dilesh Raj Shrestha as part of an ongoing series of scientific communications written and curated by BioTrib’s Early Stage Researchers.

Dilesh is researching the Development of 3D-printable, self-lubricated polymer composites with improved wear resistance for total joint replacement at Luleå University of Technology, Sweden.