Grain boundary engineering (GBE) has been one of the key methods to improve the surface properties of high-performance alloy materials. Increasing the frequency of coincidence site lattice (CSL) boundaries by GBE was found to optimise grain boundary character distribution, disrupting the connectivity of random boundaries and enhancing the resistance to grain boundary degradation. GBE can be achieved by thermomechanical processes, while some conventional approaches like cold working followed by annealing are not feasible for customised complex components.

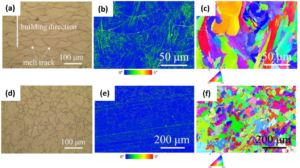

In this article, Dong et al. have brought the potential of improving the stress corrosion resistance of selective laser melting (SLM) fabricated components by GBE to light. Co-Cr alloy specimens were fabricated by SLM using the checkboard laser scan strategy and the GBE process was done by annealing at 1200 for 1 h. Through the annealing, a high frequency of twin and twin-variant boundaries was generated from the residual strain stored in the SLM fabricated Co-Cr alloys which interrupted the random boundary networks, improving the crack resistance in 0.9% NaCl solution.

By comparing these microstructural characteristics of SLM Co-Cr alloys with and without annealing, it’s interesting to see that the effects of GBE are so significant. This study shows the power of engineering microstructures and grains in improving the corrosion resistance of SLM Co-Cr alloys, which is useful for biomedical applications.

If you are interested in more details, please read the original article here.

Dong, Xin, et al. “Grain boundary character and stress corrosion cracking behavior of Co-Cr alloy fabricated by selective laser melting.” Journal of Materials Science & Technology 93 (2021): 244-253.

This post was written by Esperanza Shi as part of an ongoing series of scientific communications written and curated by BioTrib’s Early Stage Researchers.

This post was written by Esperanza Shi as part of an ongoing series of scientific communications written and curated by BioTrib’s Early Stage Researchers.

Esperanza is researching the Optimisation of Scanning Strategies for 3D Printed Artificial Joints at Imperial College London, UK.