Tribology could be considered the most interdisciplinary subject known compared with other engineering or physical science disciplines. Overall, it is related to Mechanical Engineering, Materials Science Engineering, Chemistry, Physics, Mathematics, as well as Biology. Based on the Greek root “tribos”, meaning to rub, tribology is the study of surfaces that have relative motions. Tribological considerations, such as surface roughness, material compatibility, and contact stresses, should be noticed in the design, manufacture, and use of anything that is in contact with another object. The applications of tribology include individual components (gears, bearings, brakes, etc.), assemblies (engines, pocket watches, etc.), manufacturing processes (rolling, turning, grinding, stamping, etc.), construction (mine slurry pumps, oil drilling rig, excavator, etc.), and natural phenomena (water/wind erosion, plate tectonics, etc.). The commonality between these applications is that two different surfaces are in contact or have a relative motion. Two aspects of these surfaces, including physical (surface roughness) and chemical (intervening layers), should be taken into consideration due to their vital roles in tribology.

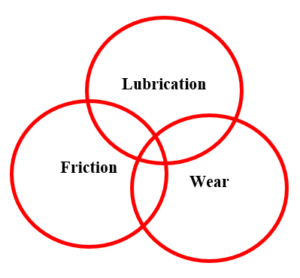

Tribology is mainly composed of three fields, namely friction, wear, and lubrication. These terms can be defined as follows:

Friction: Friction is the resistance to relative motion between two bodies in contact. There are two microscopic forces, called molecular adhesion and mechanical abrasion, between these two objects in touch. Molecular adhesion includes electrostatic, Van der Waals, as well as metallic bonds while mechanical abrasion comprises elastic, plastic, and viscoelastic deformations. Friction can be measured by the coefficient of friction which is a constant of proportionality.

Wear: Wear is the removal or displacement of material from one body when subjected to contact and relative motion with another body. Like friction, wear is a system property and not a material property. There are several distinct wear regimes, including abrasive wear, adhesive wear, fretting corrosion, erosive wear, rolling contact fatigue, and tribo-corrosion. Some of these regimes can operate simultaneously or sequentially. The wear rate significantly changes according to the wear mode which is a function of the Tribosystem.

Lubrication: Lubrication is the use of a fluid to minimize friction and wear. The critical roles of a lubricant are to reduce friction, prevent or minimize wear, transport debris away from the interface, and provide cooling. Different lubrication regimes, including boundary lubrication, mixed lubrication, and fluid film lubrication, are determined based on the fluid film thickness. These regimes are also described by the Stribeck curve.

The expression of “Biotribology” was first defined by Dowson in 1970, which considers all aspects of tribology associated with biological systems, particularly the synovial joints and joint replacements. Biotribology pertains to friction, wear, and lubrication at biological interfaces. Studying the biotribology of the natural synovial joints helps us to better understand the joints’ function as well as the development of related diseases, and to figure out what kind of medical interventions are required. This could contribute to enhancing the quality of life of patients suffering from diseases associated with synovial joints.

Learn more at Tribology 101 – Introduction to the Basics of Tribology | Dr. Arun Sikder, Bruker USA, 2019

This article was written by Mahdieh Mosayebias part of an ongoing series of scientific communications written and curated by BioTrib’s Early Stage Researchers.

Mahdieh is researching the Design of Self Lubricating Prothesis at ETH Zurich, Switzerland.