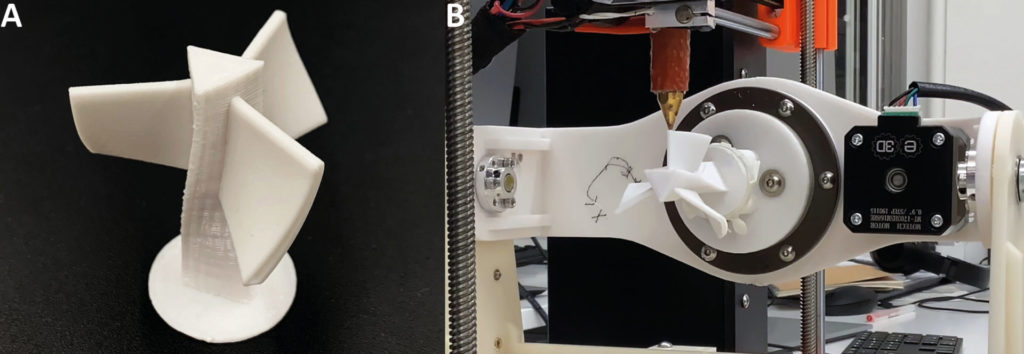

To improve the quality of printed overhanging structures and surfaces, to reduce the waste of materials of support structures and to reduce the printing time, 3D printers are ready to evolve into multi-axis. Freddie Hong, a PhD candidate at Imperial College London, has been designing 5-axis 3D printers and conformal slicing in an accessible and cheap way to bring these advantages to more individuals. With the rotating printing platform and the slicer designed for 5-axis 3D printers, the overhanging structures can be printed conformally, resulting in reinforced structural strengths.

Visit the video below to watch Freddie sharing more details!

Freddie made the hardware and software kits of open5x open resource, so check out the GitHub and upgrade your desktop 3D printer!

GitHub: https://github.com/FreddieHong19/Open5x

References:

[1] Hong, Freddie, et al. “Open5x: Accessible 5-axis 3D printing and conformal slicing.” CHI Conference on Human Factors in Computing Systems Extended Abstracts. 2022.

This post was written by Esperanza Shi as part of an ongoing series of scientific communications written and curated by BioTrib’s Early Stage Researchers.

Esperanza is researching the Optimisation of Scanning Strategies for 3D Printed Artificial Joints at Imperial College London, UK.